In this article, (and video above), we calculate the source pressure to move water through a 3″ ID steel pipe by using the Darcy-Weisbach equation and the Friction Factor Diagram provided in the PE Handbook. This question forms part of the Hydraulics and Hydrology section of the PE Exam and was created and solved by Engineer in training, Enrique Ivers.

Question:

Water needs to be transferred from a settling basin to a treatment facility. The distance from the basin to the facility is 500 feet, and the facility is at an elevation 25 feet higher than the basin. The specified capacity is 100 gallons per minute with at least 20psig of pressure at the facility.

If a 3-inch ID steel pipe is used, how much pressure needs to be provided at the basin, in psig? The Reynolds number is determined to be 2 x 10^5 and the specific roughness per the pipe manufacturer is 0.0002 ft.

Explanation:

Water needs to be transferred from a settling basin to a treatment facility. The distance from the basin to the facility is 500 feet, and the facility is at an elevation 25 feet higher than the basin. The specified capacity is 100 gallons per minute with at least 20psig of pressure at the facility.

If a 3-inch ID steel pipe is used, how much pressure needs to be provided at the basin, in psig? The Reynolds number is determined to be 2 x 10^5 and the specific roughness per the pipe manufacturer is 0.0002 ft.

We have some key information here:

- The length of the pipe, L, is 500 ft.

- The elevation difference between the source and the destination, ∆h, is +25ft.

- The specified capacity of the pipe, Q, is 100 gallons per minute.

- The pressure at the facility, h_(p(f)), needs to be 20psig.

- The pipe is steel, and has a 3 inch internal diameter.

- The Reynolds number indicates turbulent flow and the pipe’s specific roughness, ε, is 0.0002 ft.

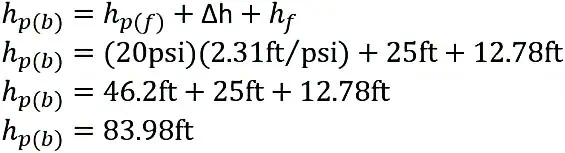

As the question asks for the necessary pressure at the basin, in gauge psi, we should calculate the equivalent total head of the system in feet, and then convert back to psi. We also know that, due to the conservation of energy, the pressure (and head) in the system needs to be balanced.

[We substitute in our pressure at the facility]

Note: The conversion factor between head feet of water and psi is: 2.31ft/psi

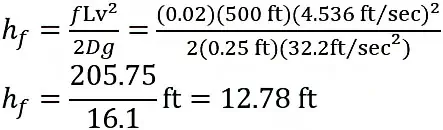

Next we need to calculate the head loss in the system, h_f. Since the flow is turbulent (Re > 4000), we should use the Darcy-Weisbach equation.

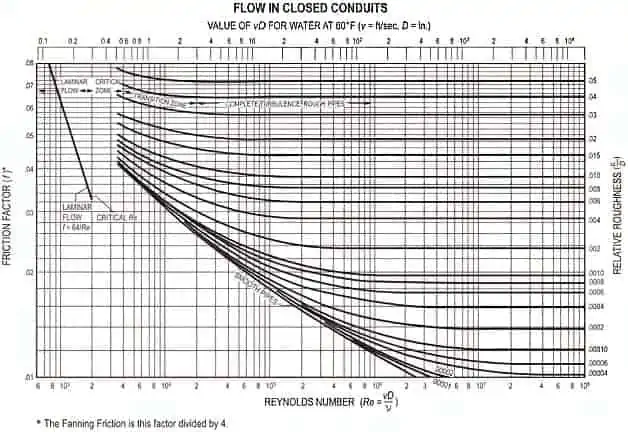

f = the Friction Factor, found in PE Handbook from the Moody, Darcy, or Stanton Friction Factor Diagram

L = the length of the pipe

v = Q/A, where Q is the flow rate and A is the cross-sectional area of the pipe

D = diameter of the pipe in ft.

g = the gravitational constant

To find the Friction Factor, f, we need to look at the Moody, Darcy, or Stanton Friction Factor Diagram provided in the PE handbook (Page 312 for the Civil PE Handbook version 1.1):

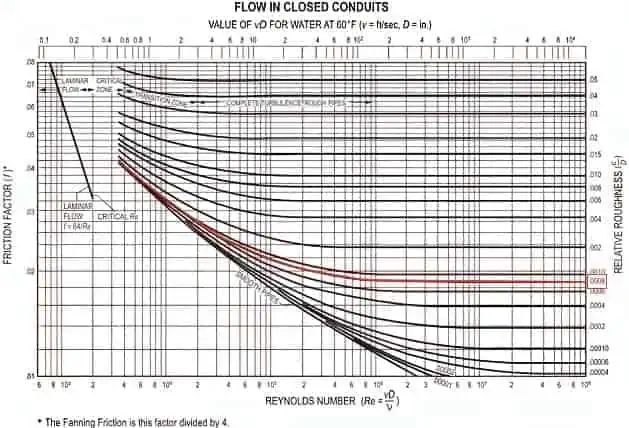

We note the axis on the right is labelled “Relative

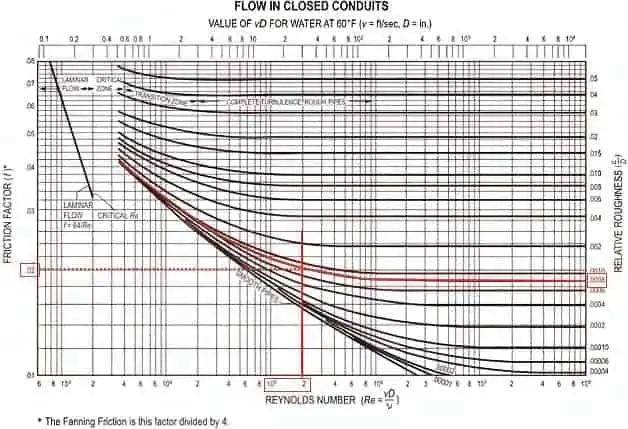

“ε” was given to be 0.0002 ft and the diameter of the pipe is 3”, or 0.25 ft.

Based on this value, and a Reynolds number of 2 x 105, we see that f is most closely 0.02

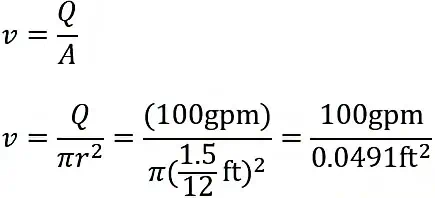

To find flow velocity, recall that v is equal to the volume of flow divided by the cross-sectional area:

Use the conversion factor of 449gpm/cfs:

Now we substitute in our calculations for variables f (0.02) and v (4.536 ft/sec):

Recall our balanced hydraulic head equation from earlier:

Now we can convert back to gauge psi:

Answer:

The correct answer is C.

This Episode Is Brought to You by PPI

PPI

I hope you found this article helpful. In upcoming articles, I will solve some more PE exam practice problems and answer other questions from our subscribers. Pass the PE Exam videos will publish weekly, so be sure to click the subscribe button so you don’t miss something that could make a substantial difference in your exam result.

Lastly, I encourage you to ask questions in the comments of this video, or on this page and I’ll read and respond to them in future videos. So, if there’s a specific topic you want me to cover or answer, we have you covered.

I’ll see you next week… on Pass the PE Exam

Anthony Fasano, P.E.

Engineering Management Institute

Author of Engineer Your Own Success

Leave a Reply